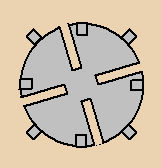

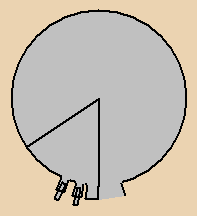

The basic rotary engine has two combustion chambers divided by a bilaterally symmetrical vane. If we use a vane that only extends in one direction from it's pivot point, we could have an engine with only one combustion chamber.

A single chamber rotary engine would vibrate a lot if it were operated by itself, but if there were two of them rotating in opposite directions and connected rigidly, the vibration would be minimized.